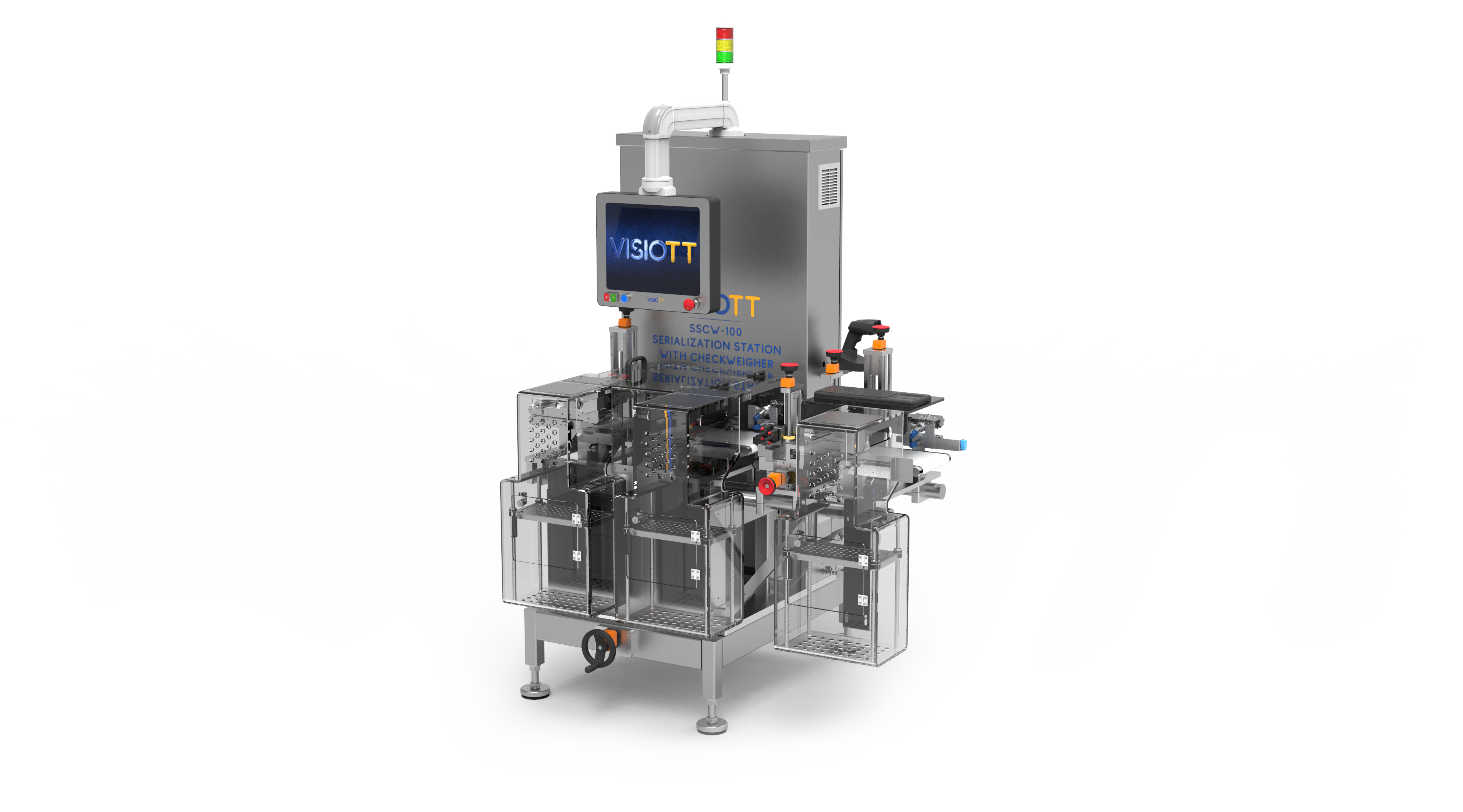

Checkweigher Solutions for Pharmaceutical Industry

Fast and Innovative Design of Quality Control for the Pharmaceutical Industry

If you want your quality control process to be fast and cost-effective, compatible with your production line, PCW-100 Checkweigher is the solution you are looking for! The PCW-100 Checkweigher ensures that a medicine box is complete by checking the weight of the smallest component in the medicine package. In this way, you meet legal requirements and secure your brand image.

The Checkweigher, which can be designed according to operational requirements, shows its difference with its precise measurement and speed. PCW-100, which can be easily integrated with traceable production processes, complies with all national and international regulations.

| Capacity | 300 pcs/minute |

| Maximum Product Weight | 1000g |

| Accuracy | ±0.1g |

| Compliance | OIML, MID, GAMP5, 21 CFR 11 |

| Customization | Extra input-output conveyors, belt weighing conveyor |